With environmental issues and environmental awareness receiving more and more attention from people around the world, the traditional packaging industry is facing great challenges. Sustainable packaging has become a business development issue. At the same time, the choice of green packaging has also become a common requirement of customers: in addition, in the context of the global trade flow to maintain the rise, more and more customers are increasingly in favour of choosing low-cost packaging solutions. It is against this backdrop that Paper IBCs are being chosen by more and more people. As a corrugated paper-based packaging, it provides customers with a more economical and environmentally friendly packaging option.

Paper IBC is a new type of collapsible medium bulk container assembled from high strength cartons and flexible liner bags. Compared with traditional drums, Paper IBC is more suitable for exporting non-hazardous chemicals and food grade liquids due to its collapsibility and ease of handling.

Paper IBC consists of three main components

Paper IBC consists of three main components

Part 1: the box is the cardboard box, which consists of high-strength paper walls, a top flap, and a bottom flap. These cardboard boxes are constructed with different bonding methods by different companies, such as LAF Paper IBC, which uses 10 layers of corrugated cardboard bonded together to form a heavy and strong outer box, and Uni-packing Paper IBC, which uses laminating technology to combine multiple layers of corrugated cardboard together.

Part 2: Food grade liner bags (IBC liner). Usually made of 2 or 3 layers of polythene film. Depending on the oxygen permeability requirements of different liquid goods, a high barrier film can be added so that the quality of the liquid goods will not be affected by external oxygen and humidity during storage and transport.

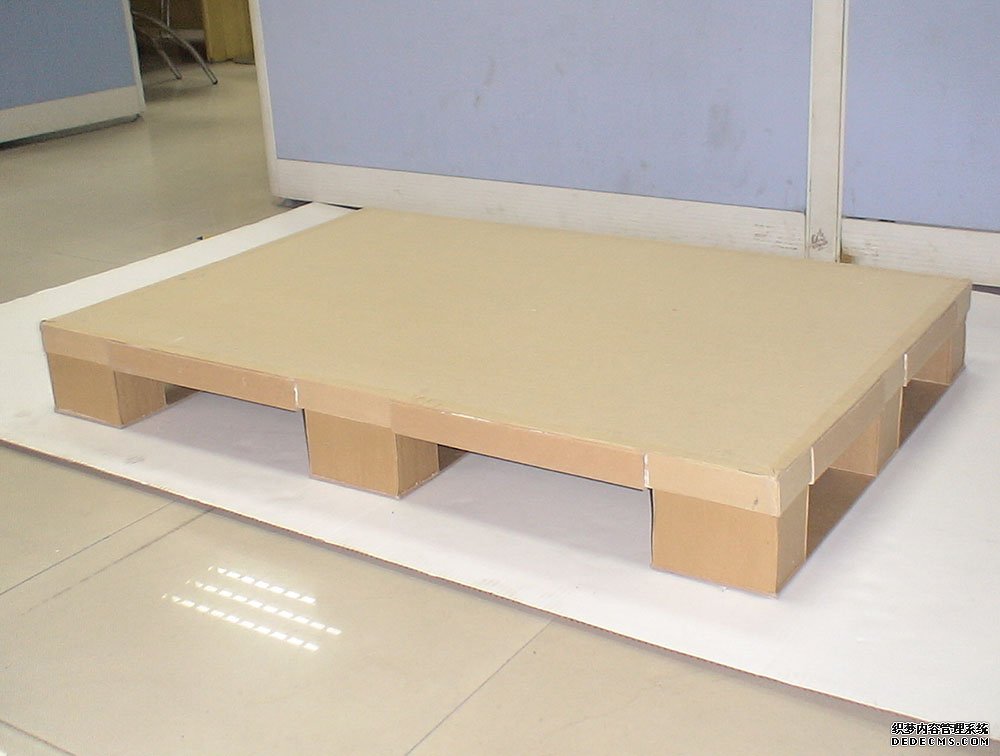

Part 3: Pallet. This type of pallet material has plastic, paper and solid wood, generally required for solid wood pallets, usually also on the pallet static load and dynamic load requirements to ensure that the carton IBC filling finished liquid stacking safety.

Product Benefits of Paper IBC

Product Benefits of Paper IBC

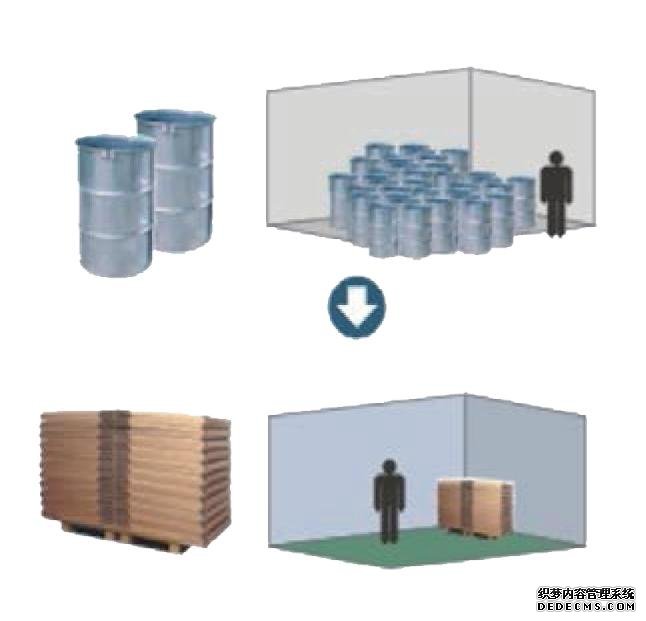

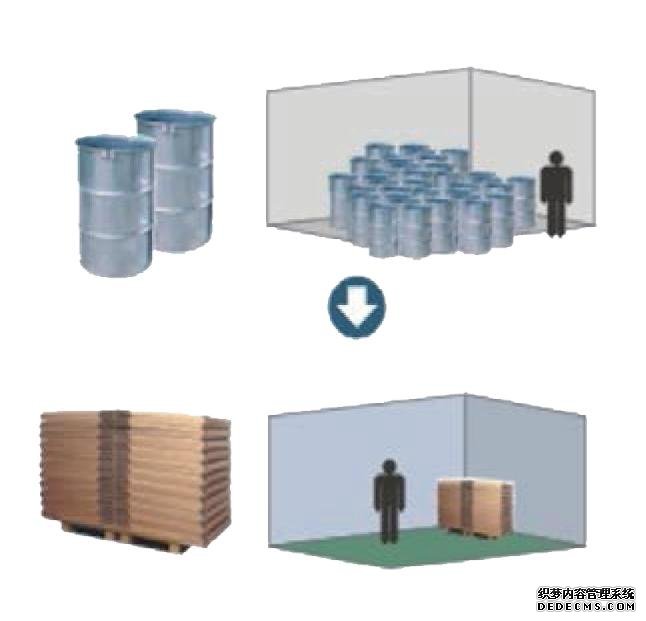

1、When the empty box, the product can be folded, reducing 80% of the storage space, thus saving the storage cost and transport cost on the empty box storage and transport.

2. Sturdy and stable. As the outer wall of the carton is made of high-strength corrugated paper and cardboard, it makes the maximum load-bearing capacity of the carton IBC can reach 1.5 tonnes.

3, Convenient and fast. Usually, the product can be assembled within 1 minute.

4.Cost saving. Such Paper IBC can reduce the packaging cost of customers compared with traditional container drums.

5. Green. The cartons and plastic liner bags exported with the goods can be easily disposed of for recycling at the destination.

Currently, Paper IBC is widely used in the following products

Currently, Paper IBC is widely used in the following products

1. Food: wine, fruit juice concentrate, dairy products, beverages, sorbitol, syrups, soy sauce

2. Industry: lubricating oil, lubricating oil additives, glycerin, coconut oil, castor oil, palm oil, transformer oil, high-fat fatty acids

3. Non-hazardous liquid chemicals: liquid fertilizers, plasticizer resins, additives, synthetic latex, liquid colourants, inks

Paper IBCs are available in normal sizes or capacities of 750L, 930L and 1000L, with each carton holding between 750kg and 1200kg.